GTV/6 - Burned Valves?: question by Dave Downie | 1983 GTV/6

In October last year I had fully rebuilt heads fitted to my '83 GVT6 (ported and polished)which had previously had exhaust valve seat problems.

My engine has recently started running rough (again!) and my mechanic has attributed the problem to burnt exhaust valves caused by detonation caused by poor fuel. I only ever use fuel from large fuel companies and only occassionally drive the car hard (and then only for short periods of time).

I have asked other mechanics what they think has caused the problem and they all have said that it seems like a valve related problem (eg. valve seats not cut properly). What are the possible causes of the burnt exhaust valves? Is the only conclusion that the heads were not rebuilt properly or could there be another reason for the problem?

| | Answer : Assuming that a proper diagnostic procedure was performed to determine that the cause of your rough running is burnt exhaust valves, I would tend to concur with the mechanics you consulted. I would hope that they performed a compression and a leak down test. I really can’t remember the last time I saw a burned valve in a V-6 Alfa. I would have to say that it sounds to me that either the valves faces were cut too thin or the valve seats were cut incorrectly. | Sprint Speciale Head Problems : question by John Nave | 1964 Sprint Speciale

My car is exhibiting symptoms that make me think it may have a crack in the head - there seems to be coolant vapor in the exhaust, but not all the time and not usually a lot. Sometimes when I stop at a signal after a long run I'll get quite a cloud though. There's also a little bit of "milkshake" crud on both the raditor and oil caps.

I took the head off and there seems to be a lot of corrosion on the mating surface, but none that is obviously causing a leak. But the head is too short to resurface, and I am already using a thick copper head gasket. So, is there more I should try before looking for a new head? And what's the right part anyway? The engine has a 0121 block, but the head is marked 10500-0150000.

| Answer : The symptoms you describe do not rule out a possible cracked head, leak behind a valve seat, or a cracked liner. These are extremely rare failures. I can count all the leaky heads or cracked liners I have seen on my fingers and toes. To check for this you would have to get the head pressure tested by someone who has experience with Alfa heads. I have had a few heads that didn’t reveal their leaks until they were first heated in an oven to 200 deg.F and then pressure tested! To detect a crack in a liner you would have to remove them from the block and visually inspect them. Corrosion on the head surface is not generally a problem unless it is on the edge of the combustion chamber and causes a problem for the head gasket to seal at that point.

A far more likely culprit would be a lack of sufficient liner protrusion . It would take more than all my fingers and toes to count the number of blown head gaskets caused by insufficient liner protrusion that I have encountered. The head gasket is not only sealing combustion from getting out of the chamber, but is also keeping coolant out. If the liner doesn’t have enough protrusion above the surface of the block, you can have a brand new head surface, perfect head gasket, and new liners, coolant would still make it’s way into the combustion chamber.

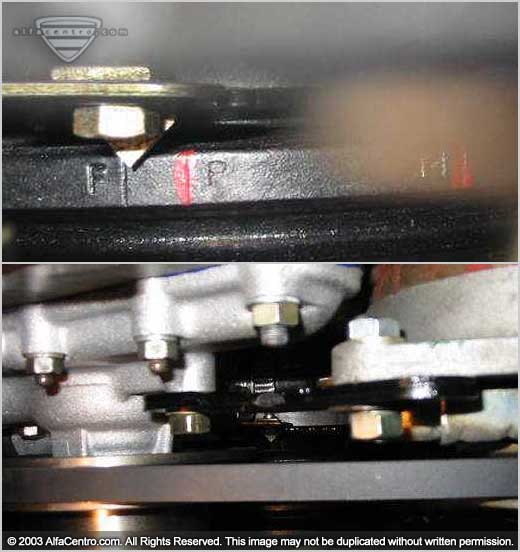

To check liner protrusion, you must remove the cylinder head,clean the liner sealing surface and clean all the gasket material off the block. Install liner stays and rotate the crank so that the tops of all the pistons are below the top surface of the block. Now lay a straight edge East to West over the top of the first liner and use a feeler gage under the straight edge at the block surface. At a minimum I like to see .0005” and a maximum of .0024” (see photo). I have scoured my Factory Tech Spec manuals and have found specification for liner protrusion from .0” at a minimum to .0024 at a maximum. I even found this spec in the GTA book : +/- 0.024” - has to be a misprint!

Regarding you question about the correct cylinder head for your SS, I went out to my garage and checked my 1965 SS that has been in my family since 1966. As you can see from the following photo, you have the correct cylinder head. My SS is absolutely original with just under 50K on the Odometer and I am the only one who has ever removed the cylinder head so I can vouch for it’s originality. Good luck, if you have any further questions, please feel free to contact me.

| Milano Verde Brake Pulling : question by Dorian | 1988 Milano Verde

I was wondering if you can help me figure out a brake problem. I recently converted my milano to non-ABS setup. New SS lines, New master cylinder, the only used item were the pedal box, brake lines, and bias valve.

The car seems to be pulling to the left whenever i apply the brakes. I also just noticed a leak out of the back of the bias valve. Of course I pan to change it, but is this my problem which causes the pulling?

| | Answer : Assuming that there was no brake pull before the conversion, you can rule out a caliper/disc problem or uneven castor, camber or toe settings causing your problem. I don’t believe that the leak at the bias valve could be causing your pull. I have seen this problem several times before after customers had converted their ABS cars to the standard booster system. In every case it was caused by attaching the brake lines to the bias valve to the wrong ports on the valve. Neither the shop manual or the parts book have a decent picture of the piping system, so I would take a look at either a Milano Gold/Silver or late model GTV-6 to figure out the correct set-up. | GTV Brake Pedal and Electrical Questions : question by Chris Bosgraaf | 1973 GTV

I'm new to Alfas so please bear with me i have two questions [1] is there a company or a way to move the gas pedal over some away from the brake or is it something i have to modify? I have big feet and on occasion i intend to depress the brake but get caught up on the accel. [2] how often are the gauges at fault for not working or is it in the wiring? if it is just wiring I will re-wire the car over winter but if it is in the gauges I will have to find someone to rebuild or replace. I have had MG's and Triumph's with the same issues but just blew it off as Lucas elec. but i plan on keeping this one for a while and would like to make it right. | Answer : I don’t know of anyone who makes a component that would move the pedal further to the right. AR Ricambi made a lowering kit for the accerator pedal. It would be helpful in solving your problem , I would check with them for availability. Moving the pedal to the right is not too difficult a modification. Alfa made the pedal rod out of steel so heating and bending the rod into a position that will suit your shoe size should not pose too great of a problem. Once you have moved the pedal to a position that suits you, make sure that you can achieve full throttle. Often times the pedal stop is set to high, causing great loss of Horse Power! The AR Ricambi pedal lowering kit can help to alieveate this problem as it reduces the amount of pedal travel. The pedal itself can be removed, modified or replaced with a fabricated piece fairly easily.

Alfa’s gauges often serve as an indicator that you do indeed have temperature, pressure, and some level of fuel, rather than an exact indicator of temperature, pressure, or actual level of fuel. If they are not functioning at all you may have one or several problems that would contribute to the malfunction. Chances are, however, that you won’t have to perform any serious re-wiring. You don’t mention if it is one or all of the gages that are not functioning, so the first thing I would do is check the fuse for the gauges. Test with the key on and also check for voltage on both sides of the fuse at the copper tabs that hold the fuse. Next, with the key on, disconnect the lead at the sender for the offending gauge and ground the wire. The gaue should peg at the max reading. If it does not you either have no power at the gauge, a bad ground at the gauge, an open short in the signal wire you are grounding, faulty connection at the gauge or a bad gauge. If it does peg, chances are you have a bad sending unit or a sending unit that is not grounded. The entire diagnotic process for checking gage function is much too lengthy to address in this column so I would suggest that you arm yourself with a wiring diagram and 12V test light and check all the gage grounds, power supply leads, and signal wires for continuity ,power and ground. The '73 GTV has the extra added variable of a printed circuit board in the instrument cluster that could be the culprit. On the upside, once you pull the instrument cluster, the wiring is very easy to test as it is all contained in two wire bundle connectors, a ground wire, and a 12v supply wire. If all your wiring and senders check out you will need gauge repair. Palo Alto Speedometer has been repairing and restoring Alfa instruments for as long as I can remember, they do a great job and generally get the job done in a timely fashion. They can be contacted at 650-323-0243 or on the Web at http://www.paspeedo.com

| Milano Failing Smog Test : question by Frank Calabrese | 1973 GTV

Car seems to run fine but it failed the emissions test. High co, hydrocarbons and no. I have changed plugs,adjusted fuel mixture which was rich andcleaned airfow meter. Numbers got worse as work was done. Gas mileage seems ok. What should i do next in order to pass emissions. I am located in Canada and can not renew car unless test is passed. Suggestions are appreciated. | Answer : Once again, the complete diagnostic procedure for your concern would be much too long to get into here. What follows are the high points of what I consider to be the most likely suspects. First, please be aware that adjustment of the idle air and the air flow meter adjusting screw only affect Idle mixture. Once the engine is off idle, the ECU takes over.

First, have the emissions tested before and after the converter to check converter function. To perform this test the converter should be hot, preferably just off a good high speed run. Don’t shut the car off as the converter will cool and loose efficiency rapidly. The converter has a small port with a hex nut plug positioned before the body of the converter just for this purpose. If your converter is original chances are that it isn’t performing at peak efficiency and will need to be replaced in order to pass the emission test.

Check for proper ignition timing at Idle and at maximum advance. Have the O2 sensor checked. Test the plug wires, coil output, condition of the air filter, cap and rotor. Test the throttle position switch and the T2 sensor for correct values.

Before testing it is imperative that the throttle position switch be adjusted correctly. Verify that there is an audible “click” from the switch when moving the throttle slightly off the idle position. Adjust the switch by loosening the two mounting bolts and turn the switch until the “click” is achieved when moving the throttle just off the idle position. If no “click” can be achieved the switch is faulty and must be replaced. The values (in Ohms) for the Throttle position switch are as follows:

| Between Terminals | Switch Position | Reading (in Ohms) | | 3 & 18 | Closed | Infinity | | 3 & 18 | Open | 0 Ohms | | 2 & 18 | Closed | 0 Ohms | | 2 & 18 | Open | Infinity | You may also want to check for continuity between the ECU multiple conductor connector at terminal 2 and at terminal 2 of the connector for the throttle position switch. Do the same for terminal 18. Also verify that you are getting the same readings at the ECU connector as you are at the switch.

The T2 sensor sends the ECU a signal containing the watertemperature information. Kind of like an electronic choke. Check the values of the sensor. They are as follows:

| Temperature | Reading (in Ohms) | | 14 deg. F | 7-12 K ohms | | 68 deg. F | 2-3 K ohms | | 80 deg. F | 250-400 ohms | Check the continuity between the ECU multiple conductor connector at terminal 13 and terminal 13 of the connector of the T2 sensor. Do the same for terminal 49 which is the ground terminal. Again, verify that your are getting the same values at the ECU connector as you are at the sensor.

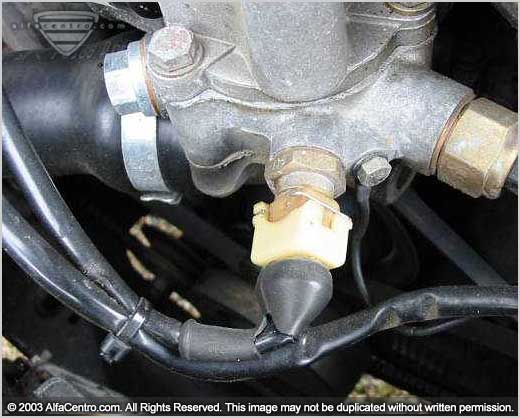

The T2 sensor is located on the thermostat housing next to the connection for the housing ground wire. See picture.

Hope all this information helps, but check that converter first, probably the most likely cause of your emission test failure. | | Spider Timing Light Operation : question by Tom Bremser | 1981 Spider I recently purchased a 1981 Alfa Spider. I was going to do some routine maintenance work, but I can't figure out how to check the timing. By looking under the car I was able to locate and mark the timing marks on the crankcase pulley and I think I found the reference point from the top of the engine... But what is the trick to putting seeing the reference point and the marks at the same time. There seems to be a belt or brace in line with each view. | | Answer : There is no real “trick”, you just need to maneuver your timing light in such a way that the pointer is visible. I had to use extra lighting to get the pictures below because light from the flash wasn’t able to illuminate the pointer and marks. As you can see from the pictures, you will have to get your light at just the right angle. It just takes a bit of maneuvering with your timing light. Good Luck.

| 164 Oil Pressure Guages : question by RoseAnn | 1991 164L

Got my Alfa 'bout three months ago was fine at first then a month ago I noticed the Oil pressure light was blinking on and off and it did not do it every time I drove sometimes it did not come on at all. The gauge read that it has pressure. Just two days the light never came on but it read no oil pressure at all. We changed the oil and filter was still the same reading no pressure at all. No change in the way it runs. Just not reading any oil pressure. Husband looked in the motor while running and could see the oil running through. But still no reading. I have not drove it since. Could it be the oil pressure gauge sender or the oil pump?? | | Answer : Chances are that you you have either a malfunctioning sending unit, an electrical connection failure or wiring concern. It doesn’t sound as though you have a gauge problem or an oil pump concern. To make certain that you don’t have an actual oil pressure problem, I would pull one of the sending units, install a mechanical gauge and make sure that you do have proper oil pressure. Then, you can feel free to drive the car while you diagnose your gauge malfunction. | Spider Chassis Stiffener: question by Jerome | 1993 Spider

Is there "kit" to reinforce the chassis of the Spider ? To get it more rigid and to help it to age smoothly ? (additional beams to install under/in the car?)

| | Answer : Yes there is a kit available. It was developed by Don Ereminas of Ereminas Imports and is available through International Auto Parts and Centerline Alfa Products. They refer to it as the “Spider Frame Stiffener” . | Spider Valve Adjustment : question by Chuck Roegge | 1986 Spider

I purchased this car with nearly 65,000 on it and have been trying to put it right. I have done all of the 60k services except the valve adjustment (It clatters like a diesel so I don't think they were adjusted at 30k). Nearest ALFA service is 425 miles in Denver area. I'm not sure of doing this myself because of removing the cams. My question, is this proceedure as simple as indicated in the shop manual or am I going to wish I'd taken it to Denver? Is there anthing to watch for? | Answer : Before hitting the road for Denver, at least check the valve adjustment. Check the cam lobe tips and cam followers for wear as well. Generally, clattering like a diesel, if caused by valve adjustment being loose, is an indicator that there is some other problem such as worn out cams, cam followers, or valve guides.

Oh yes, the valve adjustment procedure is simple, but if you decide to perform it yourself, make absolutely certain that you take it apart at TDC #1 and finish at TDC #1, or catastrophic damage may occur.

Editor's Note: AlfaCentro's handy Valve Shim Calculator makes this job much easier! | Spider Emissions Test Problems : question by Paul Ristow| 1976 Spider

I am trying to pass emission test in Wisconsin. My Spider has no air pump, good functioning Spica, new filters, therm actuator, plugs, wires, points, condenser, and just added catalytic convertor. CO reads 123 grams per mile, (65 allowable) HC and NoX are good. The engine misses when I apply the brake so I am assuming the booster is bad, and they do apply the brakes during the test. | | Answer : It could be the booster but I would check the function of the booster valve at the back of the intake manifold first. To verify that the loss of engine vacuum is the cause of your miss, simply block off the hose and apply the brakes. I would also have the car’s mixture checked with a gas analyzer, with the co readings you have I suspect that the pump may be running a tad rich. | click Here To Return to This Month's Tech Q & A |